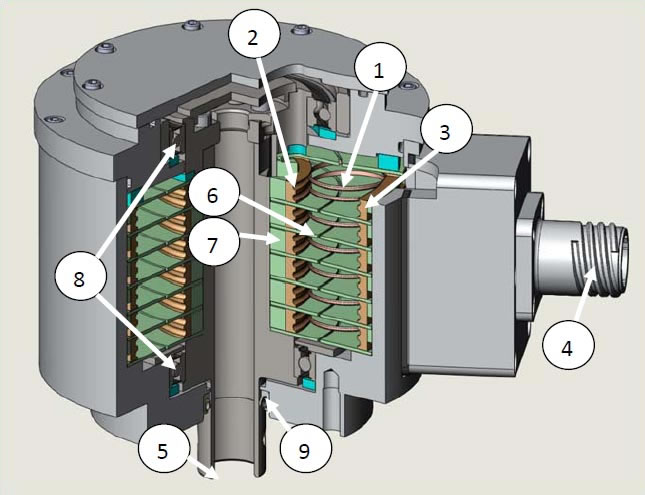

Diamond Roll-Rings Internal Design

Diamond Roll-Ring® rotary power, signal and data transfer devices share a simple, rugged common mechanical layout. The device pictured at left contains six conductive channels. Each standard conductive channel contains:

- Two gold plated ¾” diameter Roll-Rings [1].

- Roll-Rings captured between inner [2] and outer [3] gold plated conductive races.

- The stator races are terminated to the standard connector [4].

- The rotor races are connected to lead wires that exit the interior of the shaft [5] (wires not shown).

- Each channel is isolated by axial [6] and radial [7] insulators.

This particular design layout minimizes high frequency coupling and enables Roll-Rings to successfully pass data at rates up to 15 Mbit/s. Most Roll-Ring devices are produced with bearings [8] to ensure the conductive races stay in proper alignment under operation (some units are bearing-less and rely on the system pedestal for alignment). Depending on the environment, dynamic seals [9] may be included.

Roll-Rings are uniquely capable of accommodating most manufacturing tolerance variations and as a result stacking up to and beyond 70 channels is possible while maintaining life and electrical performance. The Roll-Ring interface does not require lubrication and is thus suitable for full vacuum application.